| Features of

Fibracell Reeds:

Why does Fibracell

sound so good? Because it's not plastic and it's not cane. It's the most highly

developed composite structure ever engineered for woodwinds!

With Fibracell You Get:

- The same "woody" tone

as cane but with better sound projection.

- A reed that is great

for doublers because it does not require soaking.

- A reed that is

playable in all weather conditions, not affected by heat or

humidity.

- A reed that does not

swell, warp or soften when wet.

- A reed that lasts up

to six times longer than cane with no unplayable reeds, making it less

expensive to use than cane.

- Quick response for

better articulation, excellent pitch stability and intonation in all ranges,

even for the clarinet.

- Brilliant overtones

for a full, vibrant, resonant tone.

- A reed with the same

weight and stiffness as cane - cane floats and so does Fibracell (try that with

a plastic reed!)

- A reed that keeps its

shape and retains resiliency longer than cane.

- Outstanding

durability, due to a bonded film on the bottom that helps resist tip

splitting.

- A product that is made

in the USA, by a former music educator.

What You Don't Get Is:

cane's inconsistent quality and short life.

Description of Fibracell:

Fibracell studied natural cane reed material under a microscope and

used the most advanced fibers and composites from the aerospace industry to

exactly duplicate the properties of natural cane reed material. Very stiff but

sound absorbing Kevlar fibers are suspended in a lightweight resin formulation.

It took the inventor, David W. Shaffer, over a decade of research to get the

numbers of fibers, spacing, density of matrix, position of voids and other

variables just right, but it was worth it.

Fibracell is manufactured

to exacting production standards and is precisely machined and trimmed for a

consistently perfect shape.

Experts in the fields of both music and

manufacturing Fibracell have spent many years perfecting the formulas and

processes used to make Fibracell reed material and to shape it into reeds that

play the way musicians have always wanted but only rarely found in natural

cane.

In short, Fibracell is the epitome of consistency and quality. To

the musician, that means a reed that won't let you down. |

|

Technical Aspects of

Fibracell |

What Is

Fibracell?

Fibracell material is

a sophisticated composite of aerospace materials designed to exactly duplicate

the way nature constructs cane reed. Very stiff but sound absorbing Kevlar

fibers are suspended in a lightweight resin formulation.

Fibracell

composite reed material is the result of years of research and development,

conceptualizing and augmenting state-of-the-art materials. The result is a

composite material, which has characteristics comparable to natural cane reed

in the following respects: |

- Stiffness

- Specific Gravity

- Decay Factor

- Overtones or

"Voice"

- Stiffness-to-weight ratio

- Color and

appearance

|

|

|

|

| It is the unique combination of the above properties that allows the

natural cane reed to vibrate with a rich tonal quality. These qualities are

emulated in Fibracell's unique composite structure with the additional features

of strength, long lasting durability and a consistency of quality not found in

nature. |

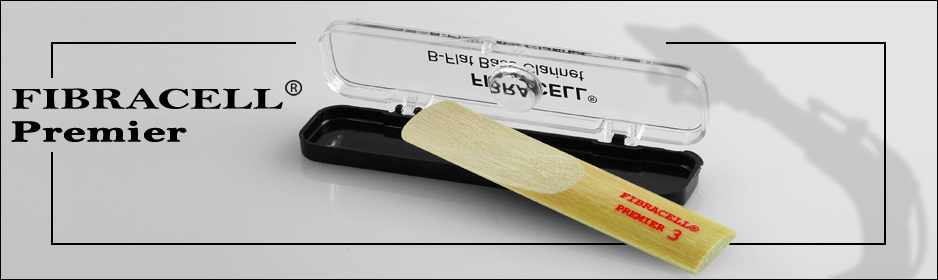

Visual

Features:

The visual similarity

of Fibracell to cane, even with a microscope, is remarkable because it's color

and cross-section structure are almost identical in appearance to cane. Thus,

the claim can accurately be made "It plays like cane because it's made like

cane. Only stronger!" Fibracell reeds can quickly be distinguished from all

other artificial reeds by a "float test". Drop a handful of plastic, cane and

Fibracell reeds in a glass of water. Only the cane and Fibracell reeds will

float. The plastic reeds will sink to the bottom. This demonstrates the

similarity in density and specific gravity between natural cane and Fibracell

material as opposed to the more dense plastic. The lightness of cane and

Fibracell is important for high note stability and the formation of correct

overtones.

Production:

Fibracell is manufactured in a process that

includes over ten production, machining and quality control operations, as

opposed to simple injection molding like most plastic reeds. The materials used

to produce the raw material are sophisticated and relatively expensive. The

equipment used to produce it is extremely sensitive and complicated. Many

factors contribute to its quality.

Once the material is produced,

making reeds from it is done in almost exactly the same way cane reeds are

produced with all the same cutting, milling, shaping, trimming and testing

steps. In other words, the Fibracell reed is the result of a combination of

expensive, sophisticated materials, many years of research and a labor

intensive manufacturing and quality control process. |

|